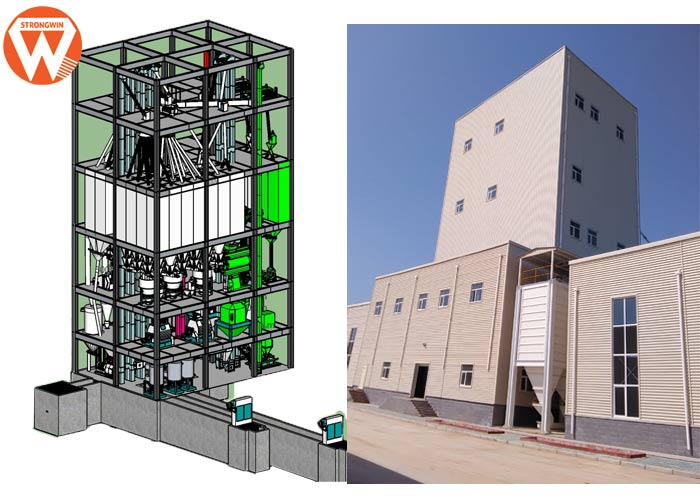

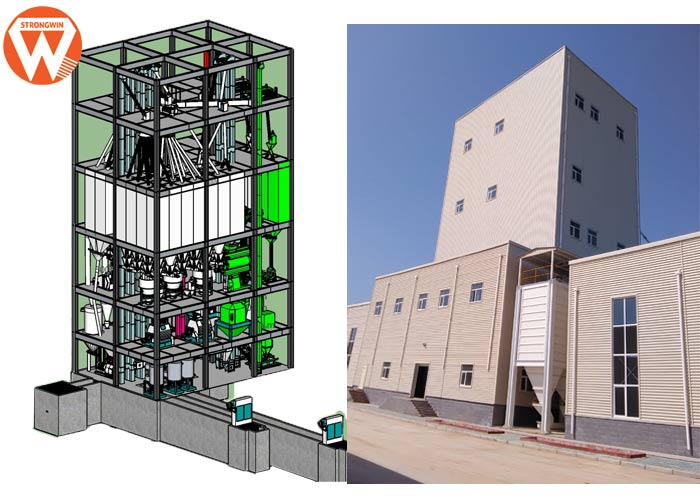

20T/H Animal Feed Production Process Line With Engineers

Installation

Description of Animal Feed Production Process Line

Raw materials → Feed Grinder → Feed Mixer → Feed Pellet Mill →

Counter flow Cooler → Feed Pellets Crumbler → Feed Pellets Grading

Sieve → Automatic Weighing and Packing Machine

Raw Material Grinding Process

General-purpose products, stableperformance, widely used in large

andmedium-sized feed, food processing enterprises of raw materials

crushed.

The machine uses direct drive, scientific and reasonable hammer

arrangement, hammer sieve clearance, finished fineness uniform.

Crushing chamber second strike technology. Selection of imported

high-quality bearings, low operating temperature.

Feed Material Mixing Process

Mixing speed is short, the mixing cycle is short, 30-120 seconds /

batch; mixing uniformity is high, CV ≤ 5%, and does not produce

segregation;

machine mixing process is moderate, loading variable range;

Feed Pelletizing Process

From the CPM models, Europe and the United States box.

The main drive uses high precision gear drive, the output is about

20% higher than the belt drive type.

Selection of imported high-quality bearings, oil seals, to ensure

that the machine running efficient, stable, low noise.

Feeder using frequency control motor to ensure that the quality of

particles discharged.

The international advanced level of compensation type serpentine

spring coupling, with a new structure, compact, safe, low noise,

low fault performance.

Ring mold lifting device, gear box gear oil automatic cooling

system.

Feed Pellet Cooling Process

The latest octagonal cooling box design, no cooling dead ends. The

use of closed feeder feed, into the air area, cooling effect is

significant.

The use of adjustable type of loose material, so that the material

evenly and evenly stacked in the cabin.

The use of slide valve reciprocating discharge mechanism, the

movement is smooth, reliable, small residue.

Feed Pellet Crushing Process

Different poultry, livestock or aquatic feed pellets are with

different sizes. Some big ones should be crushed into small ones.

Roll type feed pellet crumbler is just the equipment for feed

pellet crushing.

Feed Pellet Screening and Grading Process

Combination of the circle, oval, straight three kinds of movement,

screening effect is good. Screen ship drive with belt drive,

emphasis on balance, low noise.

Screen tail support for the improved elastic support, vibration,

low noise. Strengthen the base to ensure a more balanced operation

of the equipment.

Feed Pellet Packing Process

High-precision weighing indicator, import PLC,high-precision analog

load cell composed of weighing control system.

Applicable to materials with poor mobility. In the weighing

mechanism, the hopper on the system with a suction port, can

effectively control the spill of equipment dust to ensure that the

dust concentration in the working environment, and can make the

scale of the body pressure to maintain balance with the outside

world, to avoid the air flow weighing accuracy influences.

Technical Parameters of Animal Feed Production Process Line

| 15-20 T/H Animal Feed Pellet Production Line |

| No. | Product name | Model | Qty | Power(kw) |

| 1. material receiving section |

| 104 | Bucket elevator | TDTG48/28 | 2 | 5.5 |

| 105 | granule material clean sieve | SCY80 | 1 | 0.75 |

| 106 | permanent magnetic | TXCT25 | 1 | |

| 111 | rotary distributor | TFPX.8 | 1 | 0.55 |

| 2. material grinding section |

| 205 | Impeller feeder | SYLW3 | 1 | 1.50 |

| 206 | Tear-circle hammer mill | SDH-ZW50C | 1 | 132 |

| 209 | seal screw conveyor | SWLL25 | 2 | 6.00 |

| 210 | Impeller feeder | SYLW3 | 1 | 1.5 |

| 211 | Tear-circle hammer mill | SDH-ZW80B | 1 | 90 |

| 212 | Fan | 4-72-N04.5A | 1 | 11 |

| 213 | pulse dust collector | TBLFa.42 | 1 | |

| 3. batching and mixing section |

| 311 | small material feeding | | 1 | |

| 312 | pneumatic valve | TZMQ32*32 | 1 | |

| 313 316 | Double shaft high efficient mixer

Double shaft high efficient mixer | SSHJ.2 SSHJ.4 | 1 1 | 18.5 30 |

| 317 | Leveler | RP | 1 | |

| 318 | Vibration hammer | | 1 | |

| 319 | scrapper conveyor | TGSU25 | 1 | 3.00 |

| 322 | powder material clean sieve | SCQZ80 | 1 | 11 |

| 4. pelleting section |

| 404 | vibration pneumatic hammer | | 4 | |

| 407 | Pellet machine | SZLH420 | 2 | 220.00 |

| 409 | counter-current cooler | SKLN6 | 2 | 3.0 |

| 410 | crusher | SSLG20×170 | 2 | 30 |

| 412 | Fan | 4-72No6C | 2 | 30 |

| 413 | discharger | SKL1000 | 2 | |

| 415 | Bucket elevator | TDTG40.28 | 2 | 8 |

| 416 | classic sieve | SFJH125 | 2 | 6 |

| 5. packing section |

| 507 | automatic packing scale | SDBY-P | 2 | |

| 508 | seal conveyor machine | TFKB40 | 2 | 6 |

| 510 | pulse dust collector | TBLFa.24 | 1 | |

| 511 | seal machinery | | 1 | 0.75 |

| 512 | Fan | 4-72-N04.5A | 1 | 7.50 |

| 513 | pulse dust collector | TBLFa.30 | 1 | |

| 6.auxiliary system |

| 601 | Air compressor | | 1 | 22.00 |

| 602 | storage air tank | | 1 | |

| 603 | Dryer | | 1 | |

| 604 | liquid adding machine | SYTV63 | 1 | 3.00 |

| 606 | Steam boiler system | 2T | 1 | |